Mr.

C(EO)MOS

Photo

Juli Sing

Klaus Hörndler, CEO of Ziehm Imaging, is a hands-on type of guy. He knows the equipment and technology his company manufactures inside out. In the production department, Hörndler likes to roll up his sleeves and lend a hand, pushing C‑arms from one place to another, calibrating monitors or discussing things with his employees. One thing is for certain: Hörndler, who has a degree in electrical engineering, enjoys being where the action is.

What moved you to join Ziehm Imaging back in 1994?

That was more or less a coincidence after I got my degree. Ziehm Imaging was looking for engineers and assigned me to the department that developed image converter modules for x-rays. I enjoyed the work and it excited me from day one. And I enjoyed it back then, it didn't occur to me that I might be leading the company someday.

Twelve years later, you were then appointed CEO. Since then, you are on the road a lot and have all kinds of commitments. How much can you really still get involved in the actual product development these days?

That's something that is still very dear to me. The fact that I'm on the road a lot means that I get to see the different requirements of the international markets and can give feedback to our developers. But especially when things get tough, and we need to be at a dead end with a product, I obviously try to help and coordinate my ideas. In general, I always try to stay as close as possible to what's going on.

In your long career, is there any product that you're especially proud of?

Yes, there is. In fact there are two of them. The first one is obviously the flat-panel detector technology, because we were so far ahead of our competitors back then. Even though it's been ten years, it's still an absolute highlight for me. And the other one, naturally, is the Ziehm Vision RFD 3D, with its fantastic image quality. We developed a product that the entire industry envies us for. We're still the one and only company to offer a mobile 3D device at this level.

Apart from the successful products, why have you stayed loyal to Ziehm Imaging for so long?

I like the medical technology industry and the people who work in this very highly specialized world. At the same time, the technology fascinates me. A C-arm has so many components and parts that all have to work. It feels really great to make applications in the health sector better and safer and help patients in this way.

When you look back at the past 22 years at Ziehm Imaging, how would you describe the company's development?

When I joined Ziehm, the economic situation wasn't very rosy. There were a lot of challenges and the product was obsolete. Mr. Ziehm, the company founder, was hiring new engineers back then, and I was one of them. But the most difficult phase was back in 2003 after our acquisition of Instrumentarium, when we practically became our own direct competitor. That wasn't very comfortable for me, it was uncomfortable for a lot of employees. But since we became independent in 2004, we have been able to continue our development under Aton. The past ten years have been especially successful for Ziehm Imaging, with continuous expansion across the board.

What does the rapid growth mean for Ziehm Imaging?

On the one hand, growth means more satisfied customers. In Germany, we have always been very strong. But we owe our growth in the recent years particularly to international markets like those in the US, China or the Middle East. Growth also allows us to secure existing jobs and create new ones. We also want to have a certain impulse in order to keep expanding our leading edge in technology. In other words, if you want to achieve more, you have to sell more. And we're working to meet this goal at all times.

What's in the future for Ziehm Imaging?

Our increased sales of high-end devices will consolidate our position as a market leader in Central Europe. In this segment, the demand for 3D navigation in mobile imaging is especially great. And of course we plan to expand our international growth by developing and marketing new products, by obtaining approvals in China, Latin America, and other parts of the world, and by operating our local sales system. But the key factor for our continued growth is our broad product portfolio.

Technical innovations are a prerequisite for growth. What mobile X-ray imaging trends will play important roles in the future?

There's a lot happening in the area of interventional surgery, specifically in vascular surgery and cardiology. In these areas, C-arms are getting closer and closer to achieving the capacities of the fixed installed units. We're meeting this demand by offering our mobile Hybrid Edition, which was developed for hybrid operating rooms. Top image quality is key here, and we are improving our products with new technologies on an ongoing basis. The second big trend involves intraoperative navigation-guided 3D imaging. While this topic is well-established in some high-end markets, it hasn't yet arrived everywhere in the world. We have started to make inroads, but there's still a lot to do in this area.

Ziehm Imaging's closest competitors are large companies. What advantages does Ziehm Imaging offer compared to its competitors?

We focus exclusively on the mobile C-arm. That makes us much more flexible. For instance, we are able to implement new ideas and demands much more quickly than our big competitors. And we're also able to respond to our customers' wishes much more precisely. A good example of this is the flat-panel detector: At Ziehm Imaging, we have used flat-panel detectors for ten years and are already launching the next generation on the market. Some of our competitors have yet to do this. We're a great example of Germany's successful SME sector. We're small, but specialized, and when it comes to technology, we're cutting-edge.

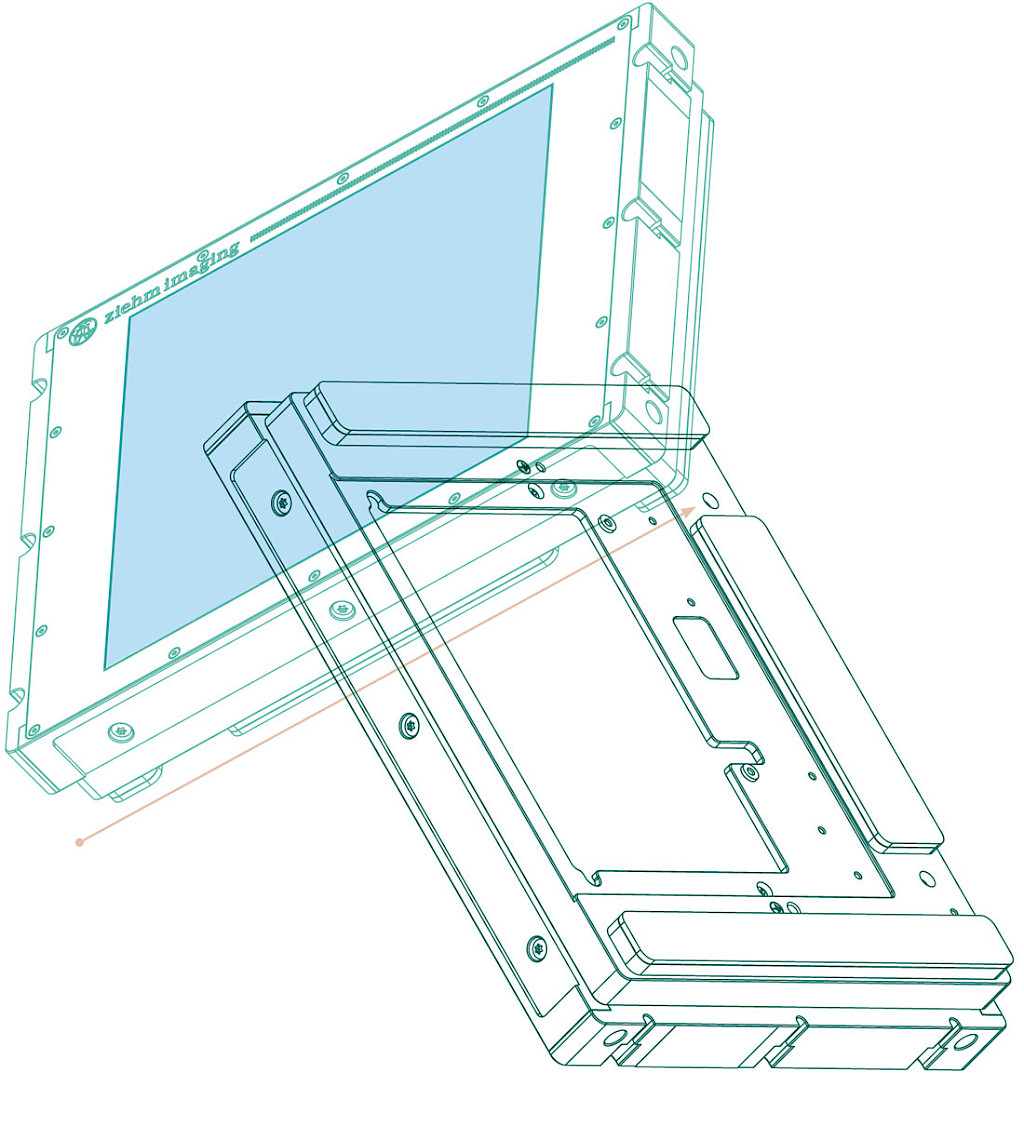

Ten years of flat-panel technology marks a milestone for Ziehm Imaging and constitutes a paradigm shift for its customers. In your view, what is the advantage of flat-panel detector technology compared to conventional image intensifiers?

The flat-panel detector enables the C-arm to have a larger opening, which gives the physicians more space near the patient and allows them to work with their instruments unimpeded. The images are absolutely free of distortions, and the contrast and image quality are undoubtedly better than that of the image intensifiers commonly used in the past. On top of that, we are able to design imaging more intelligently, working with lower doses and at the same time, optimizing image quality. All in all, the flat-panel detector is a more modern package that offers more options. Of course, it also costs more than a conventional image intensifier. In the high-end sector, that isn't really a major factor, but in the low-end sector, conventional image intensifiers will continue to be the standard for a number of years due to the lower price tag.

In 2006 you were the Vice President of Global R&D. You were probably closely involved in developing the first flat-panel detector at Ziehm Imaging. Can you recall the first discussions and conversations about this invention?

The development goes back much further than that. We first started talking about it back in 2000. Back then, we all knew that it was the technology of the future. As a technological leader, our declared goal was to break new ground. So we unanimously decided that we not only wanted to develop the flat-panel detector technology; we had to actually do it.

At the time, Ziehm was ahead of the competitors. The big rivals took a long time to kick into action. Does this make you proud?

In 2006, we were certainly proud of our achievements. Today, it's an expectation that we have set for ourselves and one that we use as a benchmark for achievements. That's why it's important to keep setting new accents. The flat-panel detector alone is no longer enough. It's now especially important to logically integrate it into our system and to explore what we can achieve with the overall system. 3D imaging is a good example of this. Without the flat-panel detector, we wouldn't be able to move around the operating table and wouldn't be able to provide the image quality we have today. So you see, in the end, the flat-panel detectors will continue to be a very important element, even if it is not the key element.

What is your prognosis? What detector technologies will shape the future?

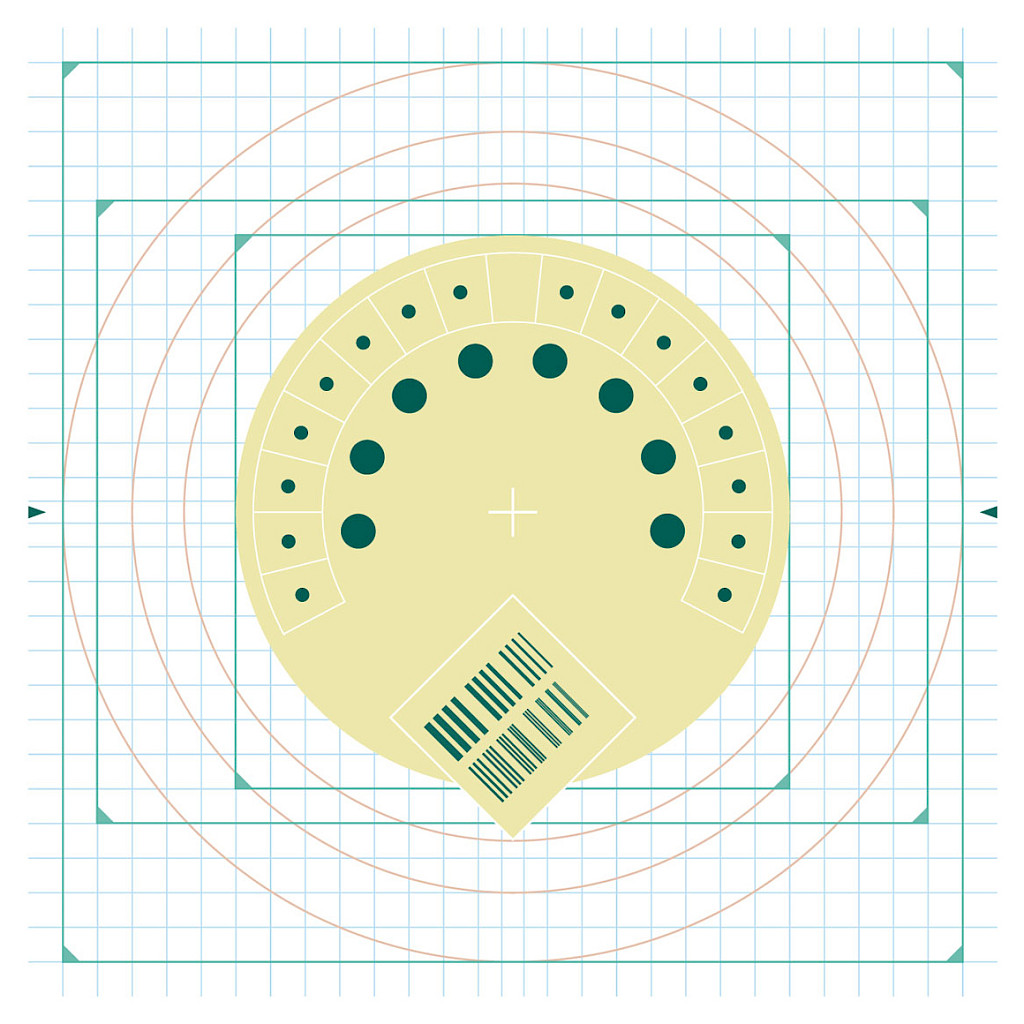

I see different directions for the future. CMOS will definitely play an important role. These detectors are already on the market and various manufacturers, from the big players in the industry, as well as companies in China, Korea and the United States, are addressing this new technology. To date, flat-panel detectors have used amorphous silicon (a-Si), and this technology will also continue to be refined in the future. Today, the image intensifier is still the prevailing product in our business, but in the future, more and more companies will be putting flat-panel detectors on the market.

You just used the term CMOS. For us technology novices, can you describe how the new CMOS technology works, for dummies?

A CMOS detector is like any other detector. Its primary function involves providing an image. But what sets CMOS apart is the higher sensitivity that enables smaller pixels to be displayed with a lower dose while producing the same quality. That permits us to achieve higher resolution with the same dose. Or conversely, you need a lower dose to achieve the same resolution. You can compare it with the latest smartphones and the ones a-Si uses today. While it was possible to take adequate quality pictures with the older smartphones, the quality of the pictures provided by the new models is exponentially better.

What do you think are the overall advantages of CMOS?

To put it in a nutshell, the clinical advantages are definitely offered by the improved image quality, the high resolution and the lower dose.

How long have you already been toying with the idea of this technology?

For about six or seven years. It took a long time to translate this technology into an industrial product. On top of that, we had decided to develop our own Ziehm detector. Now we have finally gotten to where we wanted to go: We have our own CMOS detector that is exactly tailored to our needs.

Were there any critics of CMOS out there, and if so, how do you respond to them?

Of course there were, and there are still some around. I heard criticism or skepticism from various camps. In the end, though, the outstanding performance of the panel speaks for itself. The industry agrees the CMOS panels let you achieve the same image quality with smaller pixels and still get a higher resolution. The criticism usually has to do with cost effectiveness. That's why CMOS panels are mostly used in expensive high-end applications. We'll have to see how this development unfolds in the future. Right now, the spotlight is on us.

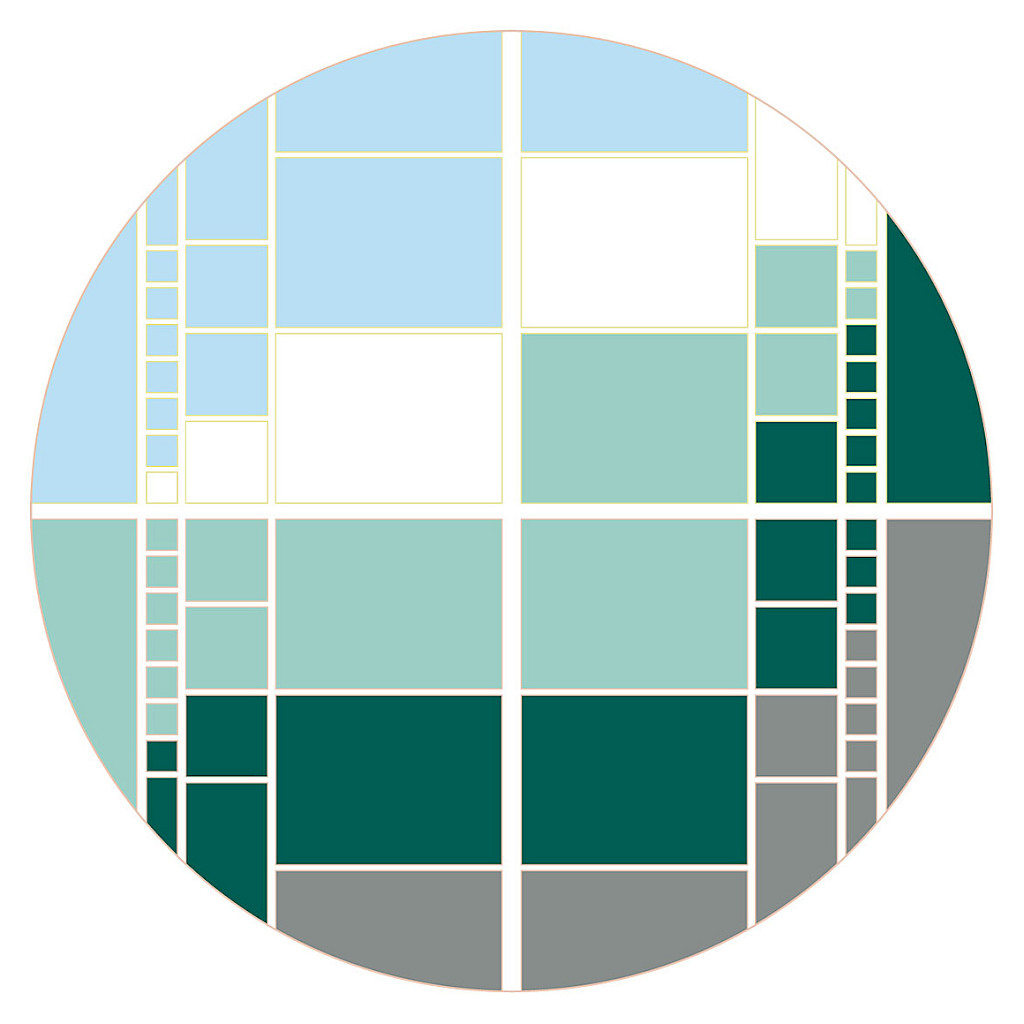

In addition to the new CMOS detectors, Ziehm Imaging will also continue to use the tried and true detector technology. What is the advantage of the conventional a-Si detectors?

CMOS is especially cost effective when it is used for smaller formats. While you can also produce larger-scale formats, the larger the format, the more advantages offered by an a-Si detector. That's why the two technologies are both in place and both of them will continue to be refined.

So how does the story end? Will the new modern CMOS technology become the new leader in mobile X-ray imaging?

Yes, it will, but certainly not in all areas or for all devices. It's similar to the automotive world. There you also have whole range of models, including compact, mid-sized and luxury models. While not everyone will choose to buy a top-class model, those who opt for high-end operating room equipment will be "driving" with CMOS technology.

This interview has been pulished in issue 1 (2017).

Download issue 1 as PDF